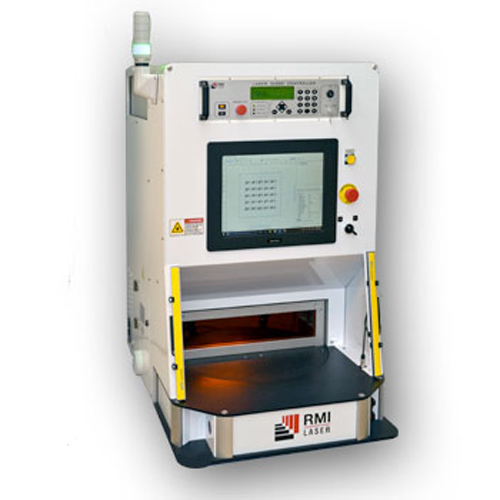

Our new Rotary Table Enclosure (Class I) allows you to mark metals, plastics, ceramics, and more in a safe, efficient manner. Place materials to be marked in a fixture on the rotary table. While they are marked, the operator can unload and load the next batch of parts, increasing overall throughput and process speed. The Rotary Table Enclosure is class 1 rated, and is available with an optional fume extractor for materials that leave heavy particulates or noxious gases during marking. The rotary table rotation and marking is triggered using the two-handed tie downs and has safety light curtains to prevent interference while the table is rotating. An indicator lamp signals the laser is ready for marking, currently marking, or an error has occurred.

If your goal is to increase throughput while ensuring safety in high traffic areas, the Rotary Table Enclosure is your solution.

| Rotary Table Enclosure | mm | inch |

|---|---|---|

| External Height - Door Closed | 1174.8 | 46.25 |

| External Height - Door Open | 1174.8 | 46.25 |

| External Width - Door Closed | 703.6 | 27.70 |

| External Width - Door Open | 703.6 | 27.70 |

| External Depth | 990.6 | 39.00 |

| Opening Door Max Height | 152.4 | 6.00 |

| Opening Door Max Width | 508.0 | 20.00 |

| Weight | 90.7 kg | 200 lbs |

| Maximum Work Piece Area | Variable: Maximum work piece area is dependent on the size of the part (L x W) and the location of the mark (X & Y axis positioning). | |

| Maximum Work Piece Height | Variable: Maximum work piece height is dependent on F-Theta lens configuration and fixturing. | |

| Laser Class | Class 1 per DIN EN 60825-1 | |

| Humidity Range | 80% non-condensing | |

| Operational Temperature Range | -10°C to 35°C | |

Other Laser Marking Workstations